What is DTG Printing and How Does It Work?

In the world of custom clothing printing, technology has advanced over the years, offering more efficient and high-quality printing methods. One of these methods is Direct to Garment (DTG) printing. This printing technique offers a fast and versatile alternative for printing detailed and colourful designs on t-shirts and other garments. In this blog, we explain what DTG printing is, how it works, its advantages, and considerations to keep in mind.

What is DTG Printing?

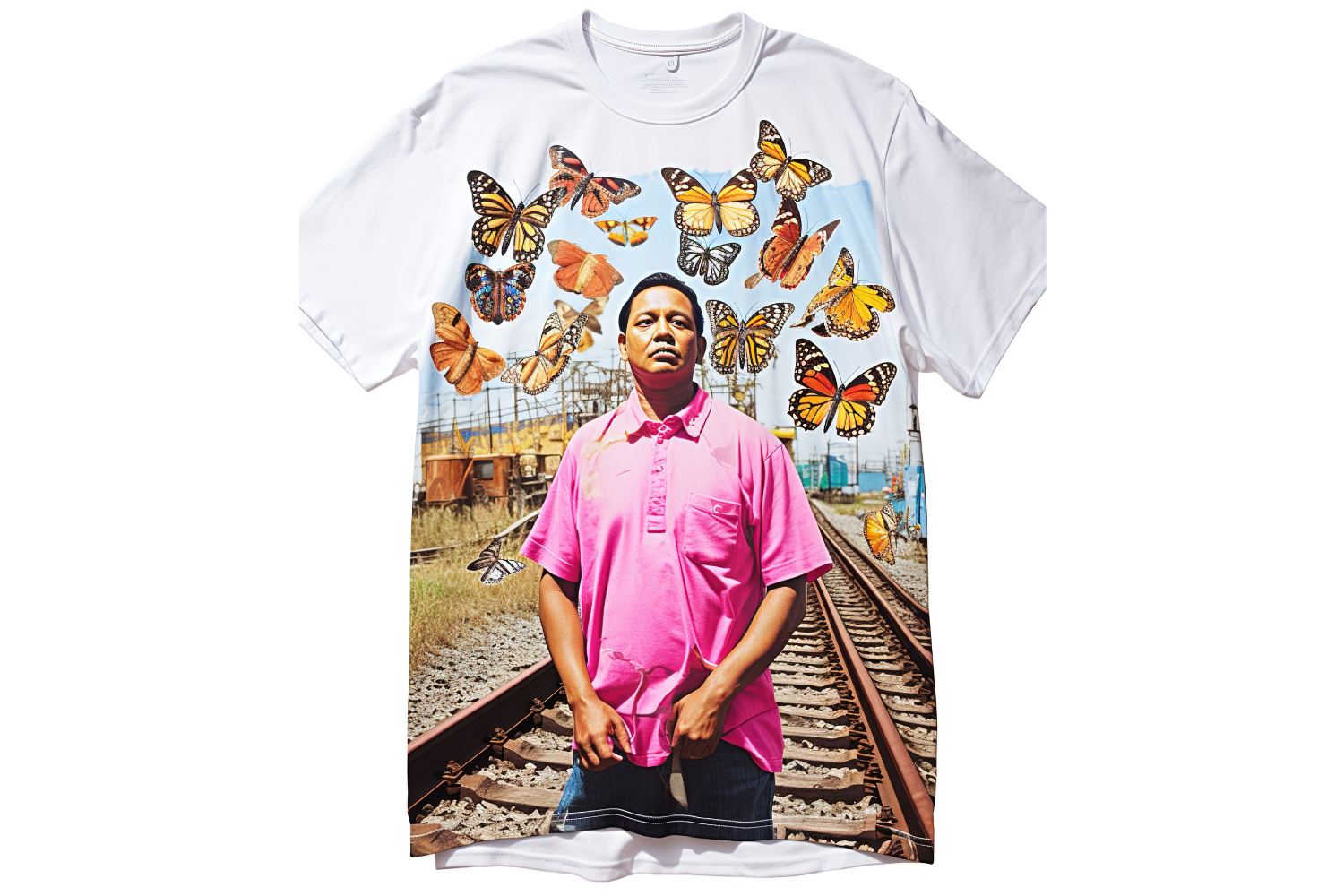

DTG printing is a digital printing technique that applies ink directly onto the fabric of a garment using a specialised inkjet printer. Unlike traditional methods like screen printing, which requires the creation of stencils or screens for each colour in the design, DTG printing allows for the printing of complex and multicoloured images in one go. This makes DTG ideal for designs with many details, full colour, and smooth gradients.

How Does DTG Printing Work?

The DTG printing process can be summarised in several key steps:

- Design Preparation: The first step is to prepare the design digitally using graphic design software. The file must be in high resolution to ensure a clear and detailed print. Common file formats include PNG, JPEG, and TIFF.

- Garment Preparation: Before printing, the garment needs to be prepared to receive the ink. This is done by applying a pre-treatment solution, especially on dark-coloured garments. This pre-treatment helps the ink adhere better to the fabric and prevents the colours from bleeding.

- Loading into the Printer: The prepared garment is placed on the platen of the DTG printer. It is crucial that the garment is well-aligned and stretched to avoid distortions in the printed design.

- Printing: Once the garment is ready, the DTG printer applies the ink directly onto the fabric following the digital design. The printer uses inkjet print heads that fire tiny droplets of ink at high speed and precision to create the desired image.

- Ink Curing: After printing, the garment must go through a curing process to set the ink and ensure its durability. This is typically done using a heat press or a curing oven.

- Final Inspection: Finally, the printed garment is inspected to ensure the design has transferred correctly and without errors. Any final adjustments are made before the garment is ready for use or distribution.

Advantages of DTG Printing

DTG printing offers several significant advantages:

- High Image Quality: DTG allows for the printing of designs with intricate details and a wide range of colours, including gradients and shadows. The image quality is comparable to that of a photograph.

- Personalisation: It is ideal for customising individual garments or producing short runs. There is no need to create screens or stencils, reducing setup time and costs.

- Speed: The printing process is fast, enabling agile and efficient production, especially useful for urgent orders.

- Sustainability: DTG printers use water-based inks that are less harmful to the environment compared to other methods that use solvent-based inks.

- Versatility: DTG is suitable for a variety of fabrics, including cotton, blends, and some synthetic fabrics, providing flexibility in material choice.

Considerations When Using DTG Printing

Despite its numerous advantages, there are some considerations to keep in mind when opting for DTG printing:

- Cost Per Unit: Although DTG is economical for short runs, it can be more expensive per unit compared to traditional methods like screen printing for large-scale orders.

- Fabric Type: The print quality is optimal on 100% cotton or eco-friendly fabrics. Blends and synthetic fabrics may not absorb the ink uniformly, affecting the design quality.

- Durability: While DTG-printed designs are durable, they may not be as resistant to washing and heavy use as screen-printed designs, especially if proper curing has not been done.

Start Printing Your T-Shirts with Us

DTG printing has emerged as an innovative and effective solution for garment customisation, offering superior image quality and great versatility. Ideal for detailed and colourful designs, this technology is especially useful for small runs and individual customisation.

At Garment Printing, we offer this printing method for your personalised t-shirts or any other garment you need. Feel free to contact us, and we will advise you on the best printing technique for your designs.